1

When selecting wave washers, consider the load requirements and the environment in which they will be used. It's important to choose a washer with the appropriate load-bearing capacity for your specific application.

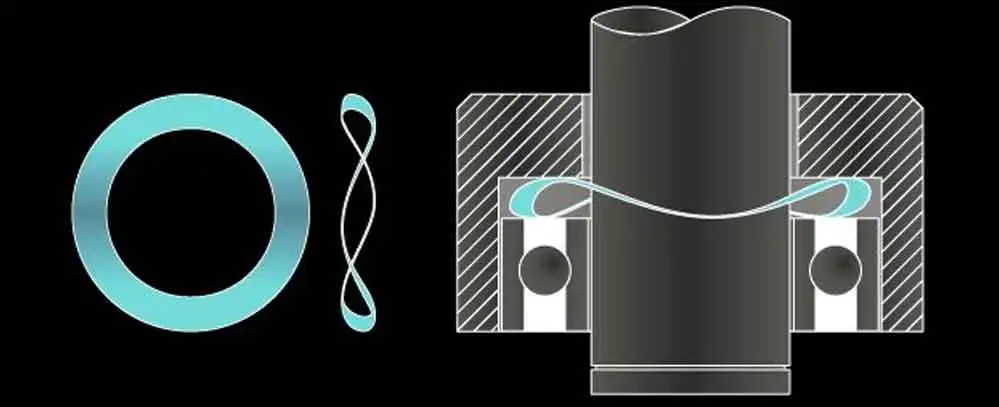

Wave washers are designed to provide a consistent load and absorb shock in bolted assemblies. Their wavy shape allows them to compress under load, maintaining tension and reducing the risk of loosening. Befast wave washers are crafted from high-quality materials, ensuring durability and reliable performance.

These washers are commonly used in applications requiring consistent tension, such as electrical components, automotive assemblies, and machinery. Their ability to absorb shock makes them ideal for dynamic environments.

Befast black oxide wave washers provide flexibility and rust resistance, making them ideal for sensitive assemblies that require controlled load distribution.Their design ensures durability and stabil...

Stainless steel wave washers from Befast offer resilience, flexibility, and corrosion resistance for a variety of applications.These washers adapt to fluctuating loads, ensuring secure support and con...

Wave washers are primarily used to maintain tension in a bolted assembly. The wavy design allows the washer to compress and expand slightly under load, which helps keep the fastener tight and secure.

This capability is particularly important in applications where vibration and dynamic loads are present. By maintaining consistent tension, wave washers prevent the fastener from loosening, ensuring the integrity and stability of the assembly.

1

To ensure the reliability and performance of wave washers, rigorous testing procedures are followed. These tests include compression testing, where the washer is subjected to various loads to measure its ability to maintain tension.

2

Other tests may include fatigue testing to determine the washer's durability under repeated loading cycles. These procedures ensure that Befast wave washers meet strict quality standards and can perform effectively in demanding applications.

When selecting wave washers, consider the load requirements and the environment in which they will be used. It's important to choose a washer with the appropriate load-bearing capacity for your specific application.

Material selection is also crucial—stainless steel wave washers are preferred for corrosive environments, while carbon steel may be suitable for less demanding conditions. Additionally, consider the size and thickness of the washer to ensure it fits the assembly properly and performs as expected.