Search

en

In industrial manufacturing, fasteners are crucial for assembling products and machinery. They provide secure connections and withstand high-stress environments. Our fasteners ensure the efficiency and reliability of manufacturing processes, helping you achieve optimal production outcomes.

Fasteners play a vital role in every stage of industrial manufacturing, from the assembly of individual components to the construction of complex machinery. In high-speed production lines, where equipment operates under continuous load and high torque, fasteners must maintain their integrity under constant vibration and movement. Our fasteners are designed with superior strength and durability to endure these conditions, ensuring that machinery runs smoothly without frequent interruptions or breakdowns.

Precision is key in manufacturing, where the alignment and stability of parts directly impact product quality. Loose or ill-fitted fasteners can lead to misalignments, reducing the efficiency of machinery and causing defects in the final product. Our fasteners are engineered to tight tolerances, ensuring a precise fit that prevents slippage and loosening over time. This results in greater stability, smoother operations, and higher-quality finished products.

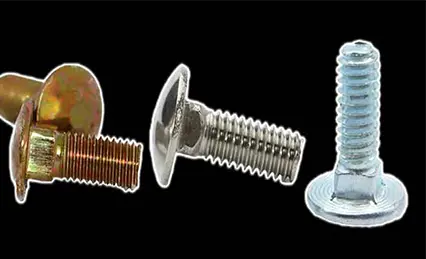

In addition to their mechanical strength, fasteners in industrial settings must also resist wear, corrosion, and chemical exposure. Factories, processing plants, and assembly lines are often subjected to harsh environments, including extreme temperatures, moisture, and exposure to oils, solvents, and other chemicals. Our fasteners are manufactured with corrosion-resistant coatings and high-performance materials, such as stainless steel and specialty alloys, to ensure long-lasting durability in even the most challenging environments.