Search

en

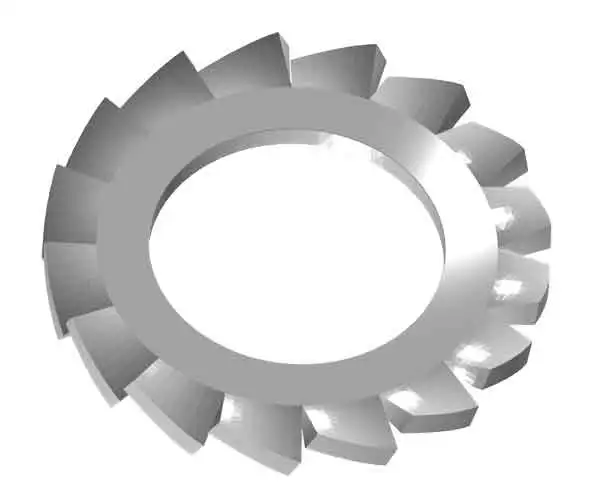

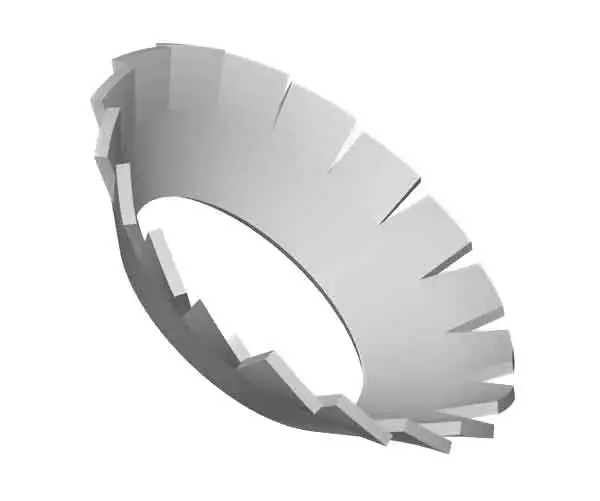

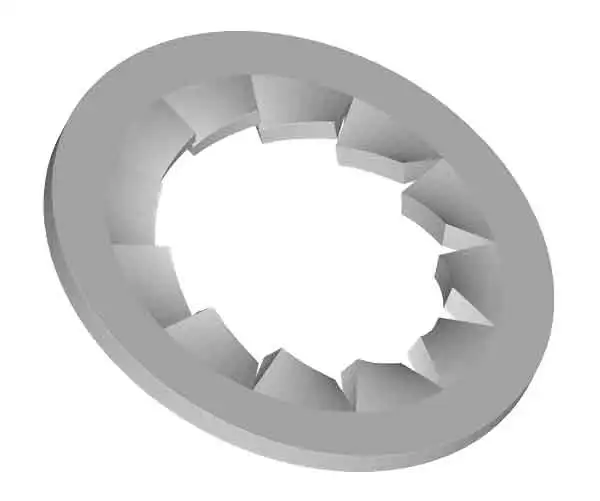

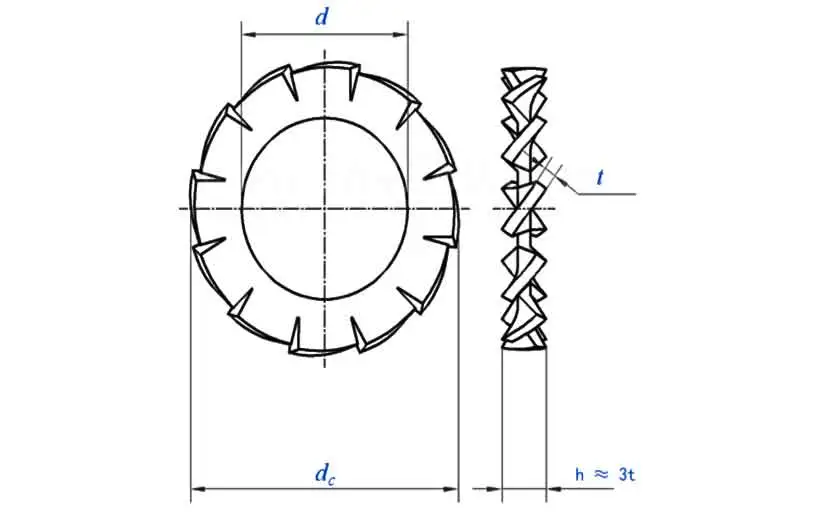

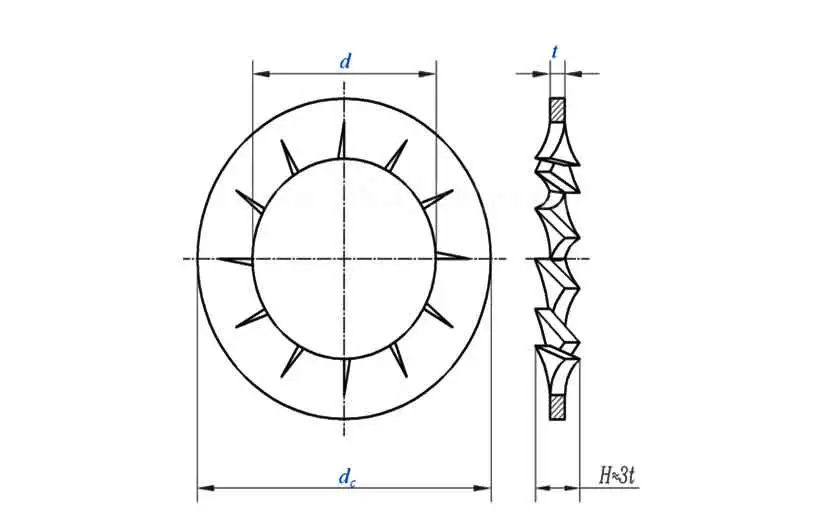

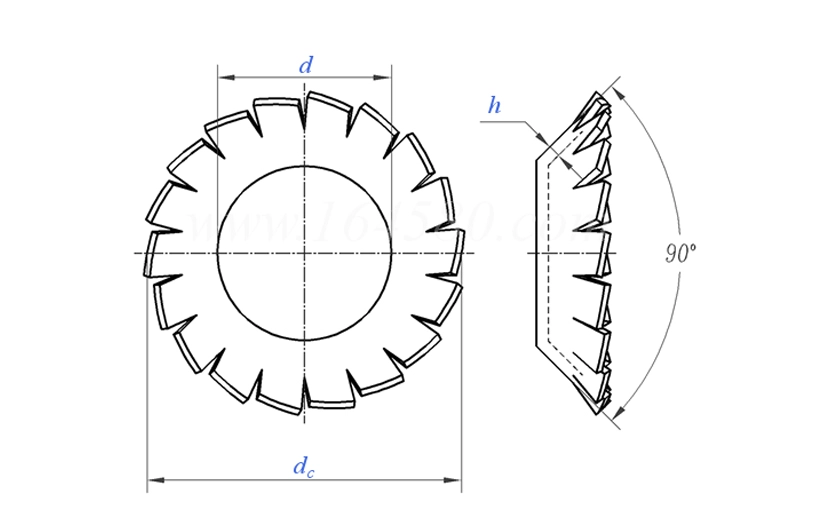

Toothed lock washers are designed to prevent loosening in bolted connections. They feature sharp teeth that bite into the surface of the material and the fastener, creating a mechanical lock that resists rotational movement.

These washers are ideal for applications where maintaining a secure connection is critical, such as in automotive, machinery, and electrical installations. Toothed lock washers are available in various sizes and materials to suit different needs.

| Name | Tooth Lock Washers | Materials | Carbon Steel/Stainless Steel |

| Standards | DIN ISO ANC BSW JIS etc. | Strength level | 50MN 65MN 4.8 8.8 etc. |

| Size | M1.7-M31 | Surface finish | ZP\Black\Plain etc. |

| Length | 0.3-1.6 | Samples | Available |

| Specification | 1.7 | 2.2 | 2.7 | 3.2 | 3.7 | 4.3 | 5.3 | 6.4 | 7.4 | 8.4 | |

| d | min=nominal | 1.7 | 2.2 | 2.7 | 3.2 | 3.7 | 4.3 | 5.3 | 6.4 | 7.4 | 8.4 |

| maximum value | 1.84 | 2.34 | 2.84 | 3.38 | 3.88 | 4.48 | 5.48 | 6.62 | 7.62 | 8.62 | |

| dc | max = nominal | 3.6 | 4.5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 12.5 | 15 |

| minimum | 3.3 | 4.2 | 5.2 | 5.7 | 6.64 | 7.64 | 9.64 | 10.57 | 12.07 | 14.57 | |

| t | 0.3 | 0.3 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.7 | 0.8 | 0.8 | |

| number of teeth | minimum | 9 | 9 | 9 | 9 | 10 | 11 | 11 | 12 | 14 | 14 |

| 1000 pieces weight kg | 0.02 | 0.03 | 0.045 | 0.06 | 0.11 | 0.14 | 0.28 | 0.36 | 0.5 | 0.8 | |

| Applicable thread | M1.6 | M2 | M2.5 | M3 | M3.5 | M4 | M5 | M6 | M7 | M8 | |

| Specification | 10.5 | 13 | 15 | 17 | 19 | 21 | 23 | 25 | 28 | 31 | |

| d | min=nominal | 10.5 | 13 | 15 | 17 | 19 | 21 | 23 | 25 | 28 | 31 |

| maximum value | 10.77 | 13.27 | 15.27 | 17.27 | 19.33 | 21.33 | 23.33 | 25.33 | 28.33 | 31.39 | |

| dc | max = nominal | 18 | 20.5 | twenty four | 26 | 30 | 33 | 36 | 38 | 44 | 48 |

| minimum | 17.57 | 19.98 | 23.48 | 25.48 | 29.48 | 32.38 | 35.38 | 37.38 | 43.38 | 47.38 | |

| t | 0.9 | 1 | 1 | 1.2 | 1.4 | 1.4 | 1.5 | 1.5 | 1.6 | 1.6 | |

| number of teeth | minimum | 16 | 16 | 18 | 18 | 18 | 20 | 20 | 20 | twenty two | twenty two |

| 1000 pieces weight kg | 1.25 | 1.6 | 2.3 | 2.9 | 5 | 6 | 7.5 | 8 | 12 | 14 | |

| Applicable thread | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | |

| ①,See "Related Material Standards and Grades" for materials, the material grades are selected by the manufacturer; Hardness: 350~425 HV10 | |||||||||||

| Specification | 1.7 | 2.2 | 2.7 | 3.2 | 3.7 | 4.3 | 5.3 | 6.4 | 7.4 | 8.4 | |

| d | min=nominal | 1.7 | 2.2 | 2.7 | 3.2 | 3.7 | 4.3 | 5.3 | 6.4 | 7.4 | 8.4 |

| maximum value | 1.84 | 2.34 | 2.84 | 3.38 | 3.88 | 4.48 | 5.48 | 6.62 | 7.62 | 8.62 | |

| dc | max = nominal | 3.6 | 4.5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 12.5 | 15 |

| minimum | 3.3 | 4.2 | 5.2 | 5.7 | 6.64 | 7.64 | 9.64 | 10.57 | 12.07 | 14.57 | |

| number of teeth | minimum | 7 | 7 | 7 | 7 | 8 | 8 | 8 | 9 | 10 | 10 |

| t | 0.3 | 0.3 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.7 | 0.8 | 0.8 | |

| 1000 pieces weight kg | 0.02 | 0.03 | 0.045 | 0.06 | 0.11 | 0.14 | 0.28 | 0.36 | 0.5 | 0.8 | |

| Applicable thread | M1.6 | M2 | M2.5 | M3 | M3.5 | M4 | M5 | M6 | M7 | M8 | |

| Specification | 10.5 | 13 | 15 | 17 | 19 | 21 | 23 | 25 | 28 | 31 | |

| d | min=nominal | 10.5 | 13 | 15 | 17 | 19 | 21 | 23 | 25 | 28 | 31 |

| maximum value | 10.77 | 13.27 | 15.27 | 17.27 | 19.33 | 21.33 | 23.33 | 25.33 | 28.33 | 31.39 | |

| dc | max = nominal | 18 | 20.5 | twenty four | 26 | 30 | 33 | 36 | 38 | 44 | 48 |

| minimum | 17.57 | 19.98 | 23.48 | 25.48 | 29.48 | 32.38 | 35.38 | 37.38 | 43.38 | 47.38 | |

| number of teeth | minimum | 12 | 12 | 14 | 14 | 14 | 16 | 16 | 16 | 18 | 18 |

| t | 0.9 | 1 | 1 | 1.2 | 1.4 | 1.4 | 1.5 | 1.5 | 1.6 | 1.6 | |

| 1000 pieces weight kg | 1.25 | 1.6 | 2.3 | 2.9 | 5 | 6 | 7.5 | 8 | 12 | 14 | |

| Applicable thread | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | |

| ①, h≈3t | |||||||||||

| ②, see "Related Material Standards and Grades" for materials, and the material grades are selected by the manufacturer; hardness: 350~425 HV10 | |||||||||||

| Nominal diameter | 2.2 | 2.7 | 3.2 | 3.7 | 4.3 | 5.3 | 6.4 | 8.4 | 10.5 | 13 | 15 | 17 | |

| d | |||||||||||||

| d | min=nominal | 2.2 | 2.7 | 3.2 | 3.7 | 4.3 | 5.3 | 6.4 | 8.4 | 10.5 | 13 | 15 | 17 |

| maximum value | 2.34 | 2.84 | 3.38 | 3.88 | 4.48 | 5.48 | 6.62 | 8.62 | 10.77 | 13.27 | 15.27 | 17.27 | |

| dc | 4.2 | 5.1 | 6 | 7 | 8 | 9.8 | 11.8 | 15.3 | 19 | twenty three | 26.2 | 30.2 | |

| h | 0.2 | 0.2 | 0.2 | 0.25 | 0.25 | 0.3 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.6 | |

| number of teeth | minimum | 10 | 10 | 12 | 12 | 14 | 14 | 16 | 18 | 20 | 26 | 28 | 30 |

| 1000 pieces weight kg | 0.025 | 0.03 | 0.04 | 0.075 | 0.1 | 0.2 | 0.3 | 0.5 | 1 | 1.5 | 1.9 | 2.3 | |

| Applicable thread | M2 | M2.5 | M3 | M3.5 | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | |

The primary benefit of toothed lock washers is their ability to prevent loosening. The teeth on the washer provide a secure grip on both the fastener and the material, ensuring that the connection remains tight even under vibration or dynamic loads.

Additionally, toothed lock washers are easy to install and do not require special tools. They are also reusable, offering long-term value and reliability in a wide range of applications.