1

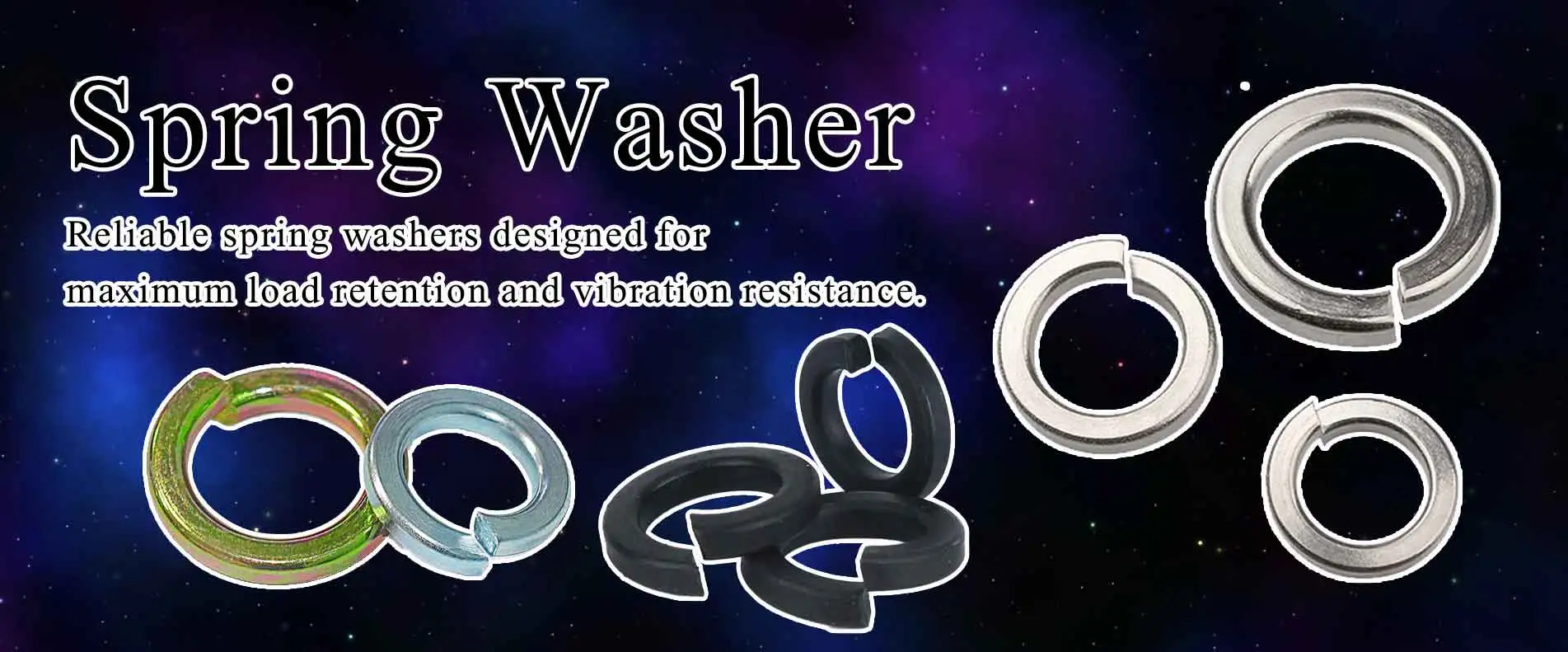

Spring washers and flat washers serve different functions in a bolted assembly. Spring washers are designed to maintain tension and resist loosening, making them ideal for dynamic environments where vibrations are present.

Spring washers are designed to maintain tension and resist loosening in bolted assemblies. They are particularly effective in environments where vibrations or dynamic loads could cause a fastener to loosen. The spring action of these washers keeps the assembly tight and secure.

Befast spring washers are available in a range of sizes and materials to meet the needs of various industries, including automotive and machinery. They are essential in any application where maintaining tension is crucial for the stability of the assembly.

Befast carbon steel spring washers are engineered for resilience and built to handle heavy-duty applications. These washers provide superior vibration resistance, ensuring secure load-bearing support....

Our stainless steel spring washers offer excellent corrosion resistance and are designed to maintain consistent tension in demanding environments.These washers are perfect for applications requiring b...

Spring washers work by maintaining constant tension in a bolted joint. When the washer is compressed, it exerts a continuous force against the bolt head and the material surface, ensuring that the connection remains tight.

This spring-like action is particularly beneficial in environments with vibrations or dynamic loads. It helps to absorb shocks and prevents the fastener from loosening over time, which is critical in maintaining the integrity of the assembly.

1

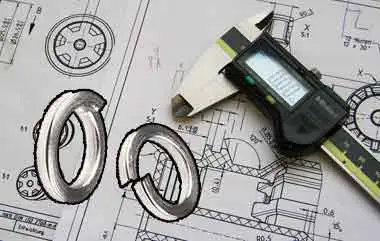

The production of spring washers often involves stamping press technology, which is crucial for achieving precision and consistency. In this process, metal sheets are shaped into washers using a high-pressure stamping press.

2

This method ensures that each washer has uniform dimensions and consistent quality, which are essential for performance. The precision offered by stamping press technology allows Befast to produce spring washers that meet strict industry standards.

Spring washers and flat washers serve different functions in a bolted assembly. Spring washers are designed to maintain tension and resist loosening, making them ideal for dynamic environments where vibrations are present.

Flat washers, on the other hand, are primarily used to distribute load and prevent surface damage. They do not provide the spring action that helps resist loosening. Choosing the right washer depends on the specific needs of your assembly—spring washers for tension maintenance and flat washers for load distribution.