Search

en

Disc spring Belleville washers are conical-shaped washers that provide high load capacity with minimal deflection. They are designed to store energy and maintain tension in bolted assemblies, even under high loads.

These washers are commonly used in applications where space is limited but a high load-bearing capacity is required, such as in valves, machinery, and heavy equipment. Befast disc spring Belleville washers are made from high-quality materials, ensuring reliable performance.

| Name | Spring Washers | Materials | Carbon Steel/Stainless Steel |

| Standards | DIN ISO ANC BSW JIS etc. | Strength level | 4.8 8.8 etc. |

| Size | M4-M130 | Surface finish | ZP\BLACK\HDG etc. |

| Length | / | Samples | Available |

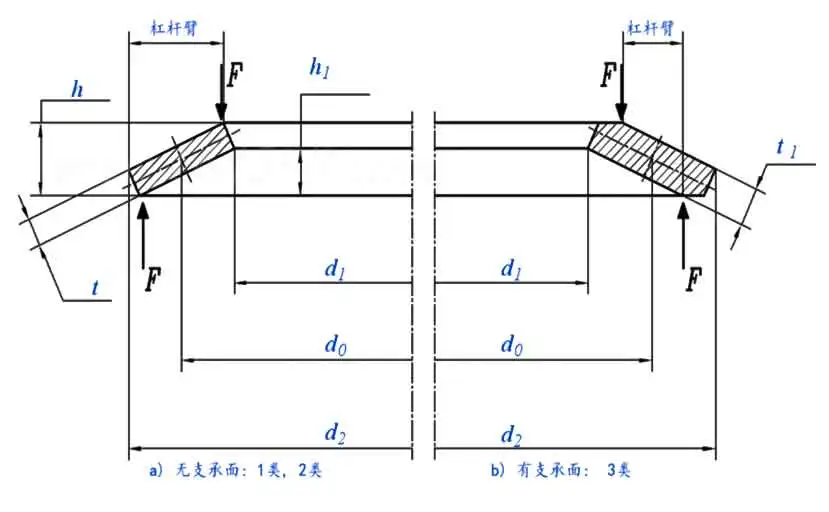

| Specification | 8 | 10 | 12.5 | 14 | 16 | 18 | 20 | 22.5 | 25 | 28 | 31.5 | 35.5 | 40 | 45 | 50 | |

| d 1 | Min = Nominal (H12) | 4.2 | 5.2 | 6.2 | 7.2 | 8.2 | 9.2 | 10.2 | 11.2 | 12.2 | 14.2 | 16.3 | 18.3 | 20.4 | 22.4 | 25.4 |

| maximum value | 4.32 | 5.32 | 6.35 | 7.35 | 8.35 | 9.35 | 10.38 | 11.38 | 12.38 | 14.38 | 16.48 | 18.51 | 20.61 | 22.61 | 25.61 | |

| d 2 | max = nominal (h12) | 8 | 10 | 12.5 | 14 | 16 | 18 | 20 | 22.5 | 25 | 28 | 31.5 | 35.5 | 40 | 45 | 50 |

| minimum | 7.85 | 9.85 | 12.32 | 13.82 | 15.82 | 17.82 | 19.79 | 22.29 | 24.79 | 27.79 | 31.25 | 35.25 | 39.75 | 44.75 | 49.75 | |

| t | 0.4 | 0.5 | 0.7 | 0.8 | 0.9 | 1 | 1.1 | 1.25 | 1.5 | 1.5 | 1.75 | 2 | 2.25 | 2.5 | 3 | |

| t 1 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | |

| h 1 | 0.2 | 0.25 | 0.3 | 0.3 | 0.35 | 0.4 | 0.45 | 0.5 | 0.55 | 0.65 | 0.7 | 0.8 | 0.9 | 1 | 1.1 | |

| h | 0.6 | 0.75 | 1 | 1.1 | 1.25 | 1.4 | 1.55 | 1.75 | 2.05 | 2.15 | 2.45 | 2.8 | 3.15 | 3.5 | 4.1 | |

| Gasket Type | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | |

| Specification | 56 | 63 | 71 | 80 | 90 | 100 | 112 | 125 | 140 | 160 | 180 | 200 | 225 | 250 | ||

| d 1 | Min = Nominal (H12) | 28.5 | 31 | 36 | 41 | 46 | 51 | 57 | 64 | 72 | 82 | 92 | 102 | 112 | 127 | |

| maximum value | 28.71 | 31.25 | 36.25 | 41.25 | 46.25 | 51.3 | 57.3 | 64.3 | 72.3 | 82.35 | 92.35 | 102.35 | 112.35 | 127.4 | ||

| d 2 | max = nominal (h12) | 56 | 63 | 71 | 80 | 90 | 100 | 112 | 125 | 140 | 160 | 180 | 200 | 225 | 250 | |

| minimum | 55.7 | 62.7 | 70.7 | 79.7 | 89.65 | 99.65 | 111.65 | 124.6 | 139.6 | 159.6 | 179.6 | 199.54 | 224.54 | 249.54 | ||

| t | 3 | 3.5 | 4 | 5 | 5 | 6 | 6 | 8 | 8 | 10 | 10 | 12 | 12 | 14 | ||

| t 1 | - | - | - | - | - | - | - | 7.5 | 7.5 | 9.4 | 9.4 | 11.25 | 11.25 | 13.1 | ||

| h 1 | 1.3 | 1.4 | 1.6 | 1.7 | 2 | 2.2 | 2.5 | 2.6 | 3.2 | 3.5 | 4 | 4.2 | 5 | 5.6 | ||

| h | 4.3 | 4.9 | 5.6 | 6.7 | 7 | 8.2 | 8.5 | 10.6 | 11.2 | 13.5 | 14 | 16.2 | 17 | 19.6 | ||

| Gasket Type | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | ||

| ①Material a) Made of steel as specified in DIN EN10083, DIN EN10089 or DIN EN10132-4. Carbon steel should only be used to make Class 1 springs. Modulus of elasticity of steel E=206000MPa b) Modulus of elasticity and strength properties of other materials (eg spring stainless steel according to DIN EN 10151, copper alloys (spring bronze) according to DIN EN 1654) may vary. | ||||||||||||||||

Disc spring Belleville washers offer several advantages, including high load capacity. Despite their compact size, these washers can handle significant loads, making them ideal for applications where space is at a premium.

Another benefit is their ability to maintain tension under varying loads, which helps prevent loosening in dynamic environments. Additionally, these washers are durable and can withstand repeated loading cycles, ensuring long-term reliability.