Search

en

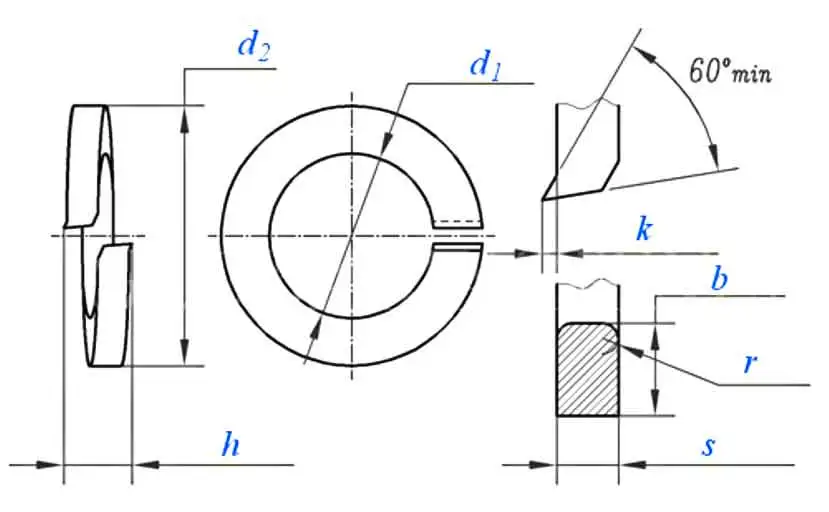

Befast carbon steel spring washers are engineered for resilience and built to handle heavy-duty applications. These washers provide superior vibration resistance, ensuring secure load-bearing support.

Designed to maintain tension under stress, our spring washers extend the lifespan of your assemblies, delivering reliable, consistent performance.

| Name | Spring Lock Washers | Materials | Carbon Steel/Stainless Steel |

| Standards | DIN ISO ANC BSW JIS etc. | Strength level | 4.8 8.8 etc. |

| Size | M3-M100 | Surface finish | ZP\BLACK\HDG etc. |

| Length | 0.8-8 | Samples | Available |

| Specification | F3 | Φ3.5 | F4 | F5 | F6 | Φ7 | F8 | Φ10 | F12 | F14 | F16 | F18 | Φ20 | F22 | F24 | F27 | ||

| d 1 | minimum | 3.1 | 3.6 | 4.1 | 5.1 | 6.1 | 7.1 | 8.1 | 10.2 | 12.2 | 14.2 | 16.2 | 18.2 | 20.2 | 22.5 | 24.5 | 27.5 | |

| maximum value | 3.4 | 3.9 | 4.4 | 5.4 | 6.5 | 7.5 | 8.5 | 10.7 | 12.7 | 14.7 | 17 | 19 | 21.2 | 23.5 | 25.5 | 28.5 | ||

| d 2 | maximum value | 6.2 | 6.7 | 7.6 | 9.2 | 11.8 | 12.8 | 14.8 | 18.1 | 21.1 | 24.1 | 27.4 | 29.4 | 33.6 | 35.9 | 40 | 43 | |

| b | Nominal | 1.3 | 1.3 | 1.5 | 1.8 | 2.5 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5 | 6 | 6 | 7 | 7 | |

| maximum value | 1.4 | 1.4 | 1.6 | 1.9 | 2.65 | 2.65 | 3.15 | 3.7 | 4.2 | 4.7 | 5.2 | 5.2 | 6.2 | 6.2 | 7.25 | 7.25 | ||

| minimum | 1.2 | 1.2 | 1.4 | 1.7 | 2.35 | 2.35 | 2.85 | 3.3 | 3.8 | 4.3 | 4.8 | 4.8 | 5.8 | 5.8 | 6.75 | 6.75 | ||

| s | Nominal | 0.8 | 0.8 | 0.9 | 1.2 | 1.6 | 1.6 | 2 | 2.2 | 2.5 | 3 | 3.5 | 3.5 | 4 | 4 | 5 | 5 | |

| maximum value | 0.9 | 0.9 | 1 | 1.3 | 1.7 | 1.7 | 2.1 | 2.35 | 2.65 | 3.15 | 3.7 | 3.7 | 4.2 | 4.2 | 5.2 | 5.2 | ||

| minimum | 0.7 | 0.7 | 0.8 | 1.1 | 1.5 | 1.5 | 1.9 | 2.05 | 2.35 | 2.85 | 3.3 | 3.3 | 3.8 | 3.8 | 4.8 | 4.8 | ||

| h | minimum | 1.9 | 1.9 | 2.1 | 2.7 | 3.6 | 3.6 | 4.6 | 5 | 5.8 | 6.8 | 7.8 | 7.8 | 8.8 | 8.8 | 11 | 11 | |

| maximum value | 2.1 | 2.2 | 2.5 | 3.2 | 4.2 | 4.2 | 5.4 | 5.9 | 6.8 | 8 | 9.2 | 9.2 | 10.4 | 10.4 | 13 | 13 | ||

| k | 0.15 | 0.15 | 0.15 | 0.15 | 0.2 | 0.2 | 0.3 | 0.3 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | ||

| r | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | 0.5 | 0.5 | 1 | 1 | 1 | 1 | 1 | 1 | 1.6 | 1.6 | ||

| Thousand pieces (steel)≈kg | 0.11 | 0.12 | 0.18 | 0.36 | 0.83 | 0.93 | 1.6 | 2.53 | 3.82 | 6.01 | 8.91 | 9.73 | 15.2 | 16.5 | 26.2 | 28.7 | ||

| Applicable thread | 3 | 3.5 | 4 | 5 | 6 | 7 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | twenty two | twenty four | 27 | ||

| Specification | Φ30 | F36 | F39 | F42 | F45 | F48 | F52 | F56 | Φ60 | F64 | F68 | F72 | Φ80 | Φ90 | Φ100 | ||

| d 1 | minimum | 30.5 | 36.5 | 39.5 | 42.5 | 45.5 | 49 | 53 | 57 | 61 | 65 | 69 | 73 | 81 | 91 | 101 | |

| maximum value | 31.7 | 37.7 | 40.7 | 43.7 | 46.7 | 50.5 | 54.5 | 58.5 | 62.5 | 66.5 | 70.5 | 74.5 | 82.5 | 92.5 | 102.5 | ||

| d 2 | maximum value | 48.2 | 58.2 | 61.2 | 68.2 | 71.2 | 75 | 83 | 87 | 91 | 95 | 99 | 103 | 111 | 121 | 131 | |

| b | Nominal | 8 | 10 | 10 | 12 | 12 | 12 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | |

| maximum value | 8.25 | 10.25 | 10.25 | 12.25 | 12.25 | 12.25 | 14.25 | 14.25 | 14.25 | 14.25 | 14.25 | 14.25 | 14.25 | 14.25 | 14.25 | ||

| minimum | 7.75 | 9.75 | 9.75 | 11.75 | 11.75 | 11.75 | 13.75 | 13.75 | 13.75 | 13.75 | 13.75 | 13.75 | 13.75 | 13.75 | 13.75 | ||

| s | Nominal | 6 | 6 | 6 | 7 | 7 | 7 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | |

| maximum value | 6.2 | 6.2 | 6.2 | 7.25 | 7.25 | 7.25 | 8.25 | 8.25 | 8.25 | 8.25 | 8.25 | 8.25 | 8.25 | 8.25 | 8.25 | ||

| minimum | 5.8 | 5.8 | 5.8 | 6.75 | 6.75 | 6.75 | 7.75 | 7.75 | 7.75 | 7.75 | 7.75 | 7.75 | 7.75 | 7.75 | 7.75 | ||

| h | minimum | 13.6 | 13.6 | 13.6 | 15.6 | 15.6 | 15.6 | 18 | 18 | 18 | 18 | 18 | 18 | 18 | 18 | 18 | |

| maximum value | 16.1 | 16.1 | 16.1 | 18.4 | 18.4 | 18.4 | 21.2 | 21.2 | 21.2 | 21.2 | 21.2 | 21.2 | 21.2 | 21.2 | 21.2 | ||

| k | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | ||

| r | 1.6 | 1.6 | 1.6 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | ||

| Thousand pieces (steel)≈kg | 44.3 | 67.3 | 71.7 | 111 | 117 | 123 | 182 | 193 | 203 | 218 | 228 | 240 | 262 | 290 | 318 | ||

| Applicable thread | 30 | 36 | 39 | 42 | 45 | 48 | 52 | 56 | 60 | 64 | 68 | 72 | 80 | 90 | 100 | ||

Befast carbon steel spring washers are designed for exceptional vibration resistance, ideal for load-bearing under stress.

They maintain consistent tension, ensuring assembly stability over time, making them essential for demanding applications. Each washer undergoes rigorous testing for quality assurance.