Search

en

Our carbon steel self-tapping screws are designed for high-strength applications, offering robust performance in metal and plastic fastening. These screws feature sharp, self-cutting threads that eliminate the need for pre-drilling, saving both time and effort during installation.

Engineered for durability, they are ideal for industrial and construction projects where reliability is critical. With precision manufacturing, these screws ensure a secure hold, reducing the risk of loosening over time. They are a cost-effective solution for high-volume applications.

| Name | Self tapping screws | Materials | Carbon Steel/Stainless Steel |

| Standards | DIN ISO ANC BSW JIS etc. | Strength level | 8.8 etc. |

| Size | M1.5-M6 | Surface finish | ZP\BLACK etc. |

| Length | 10-100 | Samples | Available |

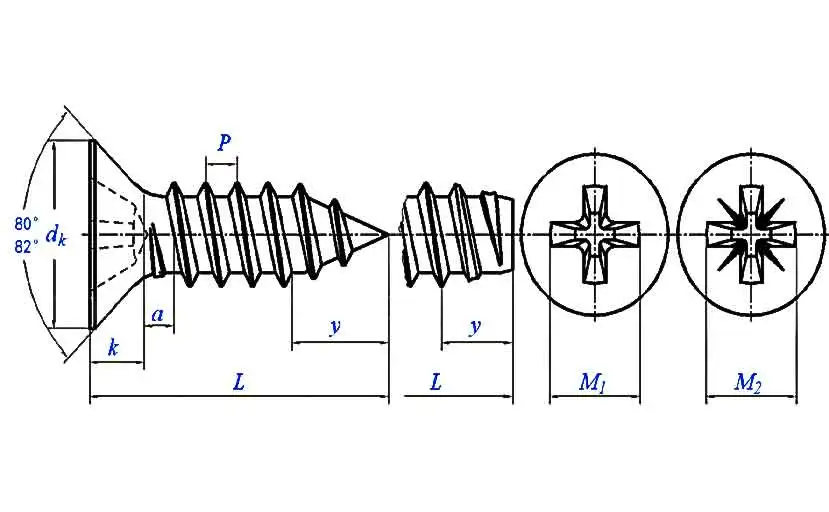

| Thread specification | ST2.2 | ST2.9 | ST3.5 | (ST3.9) | ST4.2 | ST4.8 | ST5.5 | ST6.3 | |||

| P | pitch | 0.8 | 1.1 | 1.3 | 1.3 | 1.4 | 1.6 | 1.8 | 1.8 | ||

| a | maximum value | 0.8 | 1.1 | 1.3 | 1.3 | 1.4 | 1.6 | 1.8 | 1.8 | ||

| dk | max = nominal | 4.3 | 5.5 | 6.8 | 7.5 | 8.1 | 9.5 | 10.8 | 12.4 | ||

| minimum | 4 | 5.2 | 6.44 | 7.14 | 7.74 | 9.14 | 10.37 | 11.97 | |||

| k | ≈ | 1.3 | 1.7 | 2.1 | 2.3 | 2.5 | 3 | 3.4 | 3.8 | ||

| Y | maximum value | Type C | 2 | 2.6 | 3.2 | 3.5 | 3.7 | 4.3 | 5 | 6 | |

| Type F | 1.6 | 2.1 | 2.5 | 2.7 | 2.8 | 3.2 | 3.6 | 3.6 | |||

| slot number | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 | |||

| M1 _ | ≈ | 2.5 | 3 | 4.2 | 4.6 | 4.7 | 5.1 | 6.8 | 7.1 | ||

| M 2 | ≈ | 2.4 | 2.8 | 4 | 4.2 | 4.4 | 5 | 6.3 | 7 | ||

| Thousand pieces of steel weight ≈kg | - | - | - | - | - | - | - | - | |||

Carbon steel self-tapping screws are designed for high-strength applications, providing robust performance in metal and plastic fastening. Their sharp, self-cutting threads eliminate the need for pre-drilling, which speeds up installation and reduces labor costs.

These screws are ideal for industrial and construction projects where durability and reliability are crucial. With precision manufacturing, they ensure a secure hold, reducing the risk of loosening over time. Their high tensile strength makes them a cost-effective solution for large-scale operations requiring consistent quality.