1

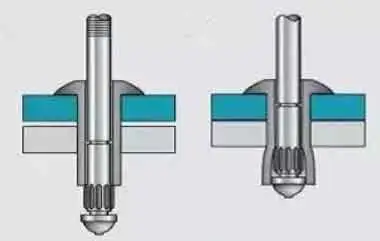

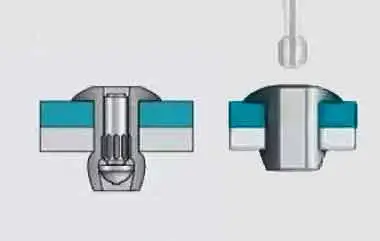

Setting blind rivets requires the use of a rivet gun or hand riveter. The tool grips the mandrel and pulls it through the rivet body, expanding the rivet and creating a secure connection.

Blind rivet is installed by pulling the mandrel through the rivet body, creating a secure connection. They are used in situations where access to the back of the material is limited, making them ideal for automotive, construction, and manufacturing applications.

Befast blind rivets are available in various sizes and materials, providing a reliable solution for fastening metal, plastic, and other materials. They are designed for quick and easy installation with a rivet gun.

Aluminum domed head blind rivets are lightweight yet incredibly strong, offering excellent resistance to corrosion in various environments. These rivets are perfect for applications where weight is a ...

Aluminum/Stainless steel domed head blind rivets combine the best of both materials, offering the lightweight advantage of aluminum with the strength and corrosion resistance of stainless steel. These...

Stainless steel domed head blind rivets are engineered for exceptional durability and corrosion resistance, making them ideal for demanding environments such as marine, automotive, and construction in...

When selecting blind rivets, consider the material thickness and the type of materials being joined. The rivet should be long enough to securely fasten the materials together without leaving excess material.

Additionally, choose a rivet made from a material that is compatible with the materials being joined to prevent corrosion or weakening of the connection. Befast offers a wide range of blind rivets designed to meet the specific needs of different applications.

1

Befast blind rivets are made from high-quality materials such as aluminum, steel, and stainless steel. These materials are chosen for their strength, durability, and corrosion resistance, ensuring that the rivets perform reliably in a wide range of environments.

2

The superior material quality of Befast blind rivets ensures that they provide a strong, secure connection in both light-duty and heavy-duty applications. Our blind rivets are designed to withstand the rigors of industrial use while maintaining their integrity over time.

Setting blind rivets requires the use of a rivet gun or hand riveter. The tool grips the mandrel and pulls it through the rivet body, expanding the rivet and creating a secure connection.

It's important to use the correct size tool and ensure that the rivet is properly aligned before setting. For large-scale applications, pneumatic rivet guns can be used to increase efficiency and reduce fatigue. Befast offers a range of setting tools to ensure your rivets are installed correctly and efficiently.