Search

en

A193 B7 fasteners are heat-treated to achieve a minimum tensile strength of 125,000 PSI, ensuring durability and performance in demanding conditions. Befast offers a range of A193 B7 fasteners that meet industry standards.

| Thread Size | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | 9/16 | 5/8 | 3/4 | 7/8 | 1 | 1-1/8 | 1-1/4 | 1-3/8 | |||

| d | ||||||||||||||||

| d | 0.25 | 0.3125 | 0.375 | 0.4375 | 0.5 | 0.5625 | 0.625 | 0.75 | 0.875 | 1 | 1.125 | 1.25 | 1.375 | |||

| PP | UNC | 20 | 18 | 16 | 14 | 13 | 12 | 11 | 10 | 9 | 8 | 7 | 7 | 6 | ||

| UNF | 28 | 24 | 24 | 20 | 20 | 18 | 18 | 16 | 14 | 12 | 12 | 12 | 12 | |||

| 8UN | - | - | - | - | - | - | - | - | - | - | 8 | 8 | 8 | |||

| U | UNC | min | 0.05 | 0.056 | 0.063 | 0.072 | 0.077 | 0.084 | 0.091 | 0.1 | 0.111 | 0.125 | 0.143 | 0.143 | 0.167 | |

| max | 0.1 | 0.111 | 0.125 | 0.143 | 0.154 | 0.167 | 0.182 | 0.2 | 0.222 | 0.25 | 0.286 | 0.286 | 0.333 | |||

| UNF | min | 0.036 | 0.042 | 0.042 | 0.05 | 0.05 | 0.056 | 0.056 | 0.063 | 0.072 | 0.084 | 0.084 | 0.084 | 0.084 | ||

| max | 0.071 | 0.083 | 0.083 | 0.1 | 0.1 | 0.111 | 0.111 | 0.125 | 0.143 | 0.167 | 0.167 | 0.167 | 0.167 | |||

| 8UN | min | - | - | - | - | - | - | - | - | - | - | 0.125 | 0.125 | 0.125 | ||

| max | - | - | - | - | - | - | - | - | - | - | 0.25 | 0.25 | 0.25 | |||

| Thread Size | 1-1/2 | 1-5/8 | 1-3/4 | 1-7/8 | 2 | 2-1/4 | 2-1/2 | 2-3/4 | 3 | 3-1/4 | 3-1/2 | 3-3/4 | 4 | |||

| d | ||||||||||||||||

| d | 1.5 | 1.625 | 1.75 | 1.875 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | 3.75 | 4 | |||

| PP | UNC | 6 | - | 5 | - | 4 1/2 | 4 1/2 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | ||

| UNF | 12 | - | - | - | - | - | - | - | - | - | - | - | - | |||

| 8UN | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | |||

| U | UNC | min | 0.167 | - | 0.2 | - | 0.222 | 0.222 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | |

| max | 0.333 | - | 0.4 | - | 0.444 | 0.444 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | |||

| UNF | min | 0.084 | - | - | - | - | - | - | - | - | - | - | - | - | ||

| max | 0.167 | - | - | - | - | - | - | - | - | - | - | - | - | |||

| 8UN | min | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | ||

| max | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | |||

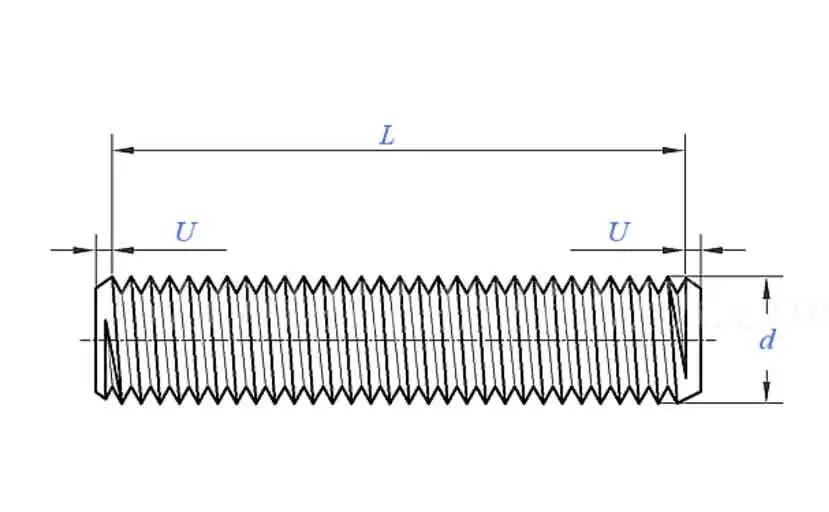

| ①U —— Chamfered Thread Distance: | ||||||||||||||||

| Stud ends shall be chamfered from the major diameter to a diameter equal to or less than the thread root diameter. The length of the chamfered end to the first full formed thread at major diameter, as determined by the distance the chamfered end enters into a cylindrical NOT GO major diameter ring gage, shall be one to two thread pitches on each end. The ends of the stud shall be reasonably square with the axis of the stud, but the slight rim or cup resulting from manufacturing shall be permissible. The ends shall be suitable for marking. | ||||||||||||||||

| Thread Size | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | 9/16 | 5/8 | 3/4 | 7/8 | 1 | 1-1/8 | 1-1/4 | 1-3/8 | |||

| d | ||||||||||||||||

| d | 0.25 | 0.3125 | 0.375 | 0.4375 | 0.5 | 0.5625 | 0.625 | 0.75 | 0.875 | 1 | 1.125 | 1.25 | 1.375 | |||

| PP | UNC | 20 | 18 | 16 | 14 | 13 | 12 | 11 | 10 | 9 | 8 | 7 | 7 | 6 | ||

| UNF | 28 | 24 | 24 | 20 | 20 | 18 | 18 | 16 | 14 | 12 | 12 | 12 | 12 | |||

| 8UN | - | - | - | - | - | - | - | - | - | - | 8 | 8 | 8 | |||

| U | UNC | min | 0.05 | 0.056 | 0.063 | 0.072 | 0.077 | 0.084 | 0.091 | 0.1 | 0.111 | 0.125 | 0.143 | 0.143 | 0.167 | |

| max | 0.1 | 0.111 | 0.125 | 0.143 | 0.154 | 0.167 | 0.182 | 0.2 | 0.222 | 0.25 | 0.286 | 0.286 | 0.333 | |||

| UNF | min | 0.036 | 0.042 | 0.042 | 0.05 | 0.05 | 0.056 | 0.056 | 0.063 | 0.072 | 0.084 | 0.084 | 0.084 | 0.084 | ||

| max | 0.071 | 0.083 | 0.083 | 0.1 | 0.1 | 0.111 | 0.111 | 0.125 | 0.143 | 0.167 | 0.167 | 0.167 | 0.167 | |||

| 8UN | min | - | - | - | - | - | - | - | - | - | - | 0.125 | 0.125 | 0.125 | ||

| max | - | - | - | - | - | - | - | - | - | - | 0.25 | 0.25 | 0.25 | |||

| Thread Size | 1-1/2 | 1-5/8 | 1-3/4 | 1-7/8 | 2 | 2-1/4 | 2-1/2 | 2-3/4 | 3 | 3-1/4 | 3-1/2 | 3-3/4 | 4 | |||

| d | ||||||||||||||||

| d | 1.5 | 1.625 | 1.75 | 1.875 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | 3.75 | 4 | |||

| PP | UNC | 6 | - | 5 | - | 4 1/2 | 4 1/2 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | ||

| UNF | 12 | - | - | - | - | - | - | - | - | - | - | - | - | |||

| 8UN | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | |||

| U | UNC | min | 0.167 | - | 0.2 | - | 0.222 | 0.222 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | |

| max | 0.333 | - | 0.4 | - | 0.444 | 0.444 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | |||

| UNF | min | 0.084 | - | - | - | - | - | - | - | - | - | - | - | - | ||

| max | 0.167 | - | - | - | - | - | - | - | - | - | - | - | - | |||

| 8UN | min | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | ||

| max | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | |||

| ①,U —— Chamfered Thread Distance: | ||||||||||||||||

| Stud ends shall be chamfered from the major diameter to a diameter equal to or less than the thread root diameter. The length of the chamfered end to the first full formed thread at major diameter, as determined by the distance the chamfered end enters into a cylindrical NOT GO major diameter ring gage, shall be one to two thread pitches on each end. The ends of the stud shall be reasonably square with the axis of the stud, but the slight rim or cup resulting from manufacturing shall be permissible. The ends shall be suitable for marking. | ||||||||||||||||

A193 B7 fasteners offer exceptional strength and are designed to withstand high pressure and temperature environments. They are ideal for use in the oil and gas, petrochemical, and power generation industries.

These fasteners are heat-treated to enhance their mechanical properties, ensuring reliability and performance. Befast A193 B7 fasteners are manufactured to strict specifications, providing peace of mind in critical applications.